Did you know the average American produces about four pounds of waste per day? That’s 1,327,600,000 pounds every 24 hours. Obviously, Earth cannot take this, and it’s time for some major changes. But luckily, Nexamp has already started. Read on for all the squeaky-clean energy details of our module and packaging recycling program.

WHEN WE STARTED

We’re building a cleaner world, not a cluttered one. It’s been understood since day one that Nexamp needed a recycling system, and we’re happy to share that our pilot program was launched in March 2021. Led by Chris Perron, Nexamp’s SVP of Clean Energy Deployment, the objective was to calculate total waste per site, identify what could be recycled, and collaborate with third-party providers. Thankfully, we found We Recycle Solar in no time. “As the only solar recycler fully permitted by the EPA (Environmental Protection Agency) to handle hazardous secondary materials, we know we’re the right partner for Nexamp, shared AJ Orben, VP of We Recycle Solar. With speed, we recover up to 99% of the raw material by weight. Panels are dismantled, milled, and undergo chemical processing before they are sold back to the global commodities market for new manufacturing.” Since 2021, Nexamp has recycled 3,946 modules (217,030 pounds of waste) alongside We Recycle Solar.

HOW WE RECYCLE MODULES

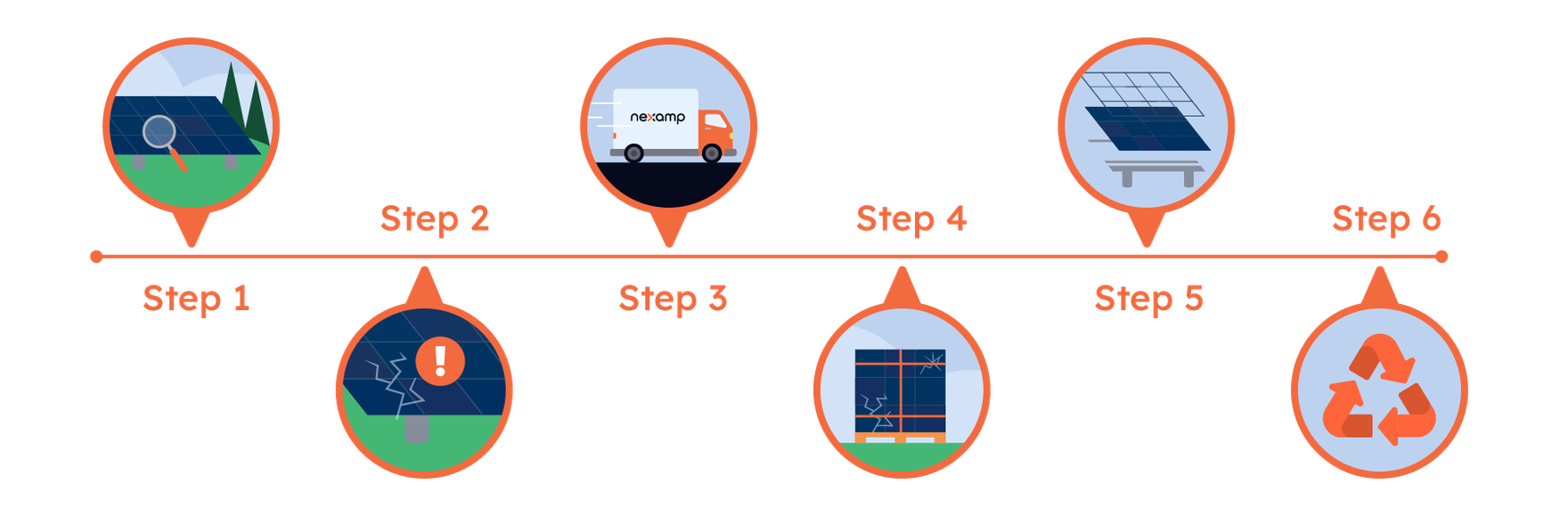

Step 1: All modules are inspected upon arrival at Nexamp construction sites.

Step 2: Any damaged modules are flagged, and the issues are recorded.

Step 3: Damaged modules are placed onto pallets for pick up.

Step 4: Modules are transported to We Recycle Solar’s facility.

Step 5: Upon arrival, the modules are broken down into separate components (silicon, glass, metals, etc.).

Step 6: 95% of the components are 100% recycled!

WASTE MANAGEMENT

The average Nexamp farm uses about 7,000 panels, and each comes on pallets wrapped in plastic and cardboard. So, we asked ourselves, ‘where’s the value in recycling panels if we don’t consider the packaging?’ This accounts for the majority of Nexamp’s site waste, and 96% of it is recyclable. “We don’t just talk the talk; we walk the walk. From the genesis of this program, considering waste was a top priority. It may not be flashy, but it will make a massive impact,” shared Chris Perron. With the help of 7 Gen Waste Logistics, we’re proud to be recycling packaging as well. As zero of Nexamp’s 177 farms have reached their end date (built to last), the only panels we’re recycling are damaged. But about 20 years from now, when it’s time for decommissioning, we’ll have the process down pat.

HOW WE RECYCLE SITE WASTE

Step 1: When materials arrive on site, all waste is sorted into five streams.

- Cardboard

- Pallets

- Metals

- Plastic & Cans

- Trash

Step 2: Waste is sorted into its designated container. Once that container is 80% full, Nexamp requests a pick-up from 7Gen Waste.

Step 3: When construction is complete, 7Gen Waste picks up all remaining containers.

THE WAY FORWARD

Nexamp has very ambitious ESG (Environmental, Social, and Governance) goals. By 2025, we plan to have an all-electric fleet, and by 2030, our supply chain will be hundred-percent carbon neutral. This recycling program is a very important piece of the puzzle. Now that it’s been officially launched, the team is focused on improving processes and lowering costs. “I’m happy to report that 97 percent of waste from participating farms was diverted from landfills. But we can do more,” shared Chris. “I’d like this program to reach all Nexamp sites and benefit all communities we serve. And, of course, we’d like to create more local jobs along the way.”

Nexamp is focused on making an impact, not leaving a footprint. If you wish to do the same, consider your daily habits. There are plenty of easy ways to reduce waste. And if we all work together, our future will be bright, not binned.