Efficiency in energy production has always been a high priority for solar developers, and with a rapid growth in solar energy development, project inspections are even more vital to ensuring that solar farms are performing properly. Drones and aerial data are transforming the green energy space by making the solar farm inspection process faster, while delivering more accurate data of an array’s performance. Here are three areas in which drones are revolutionizing the solar industry:

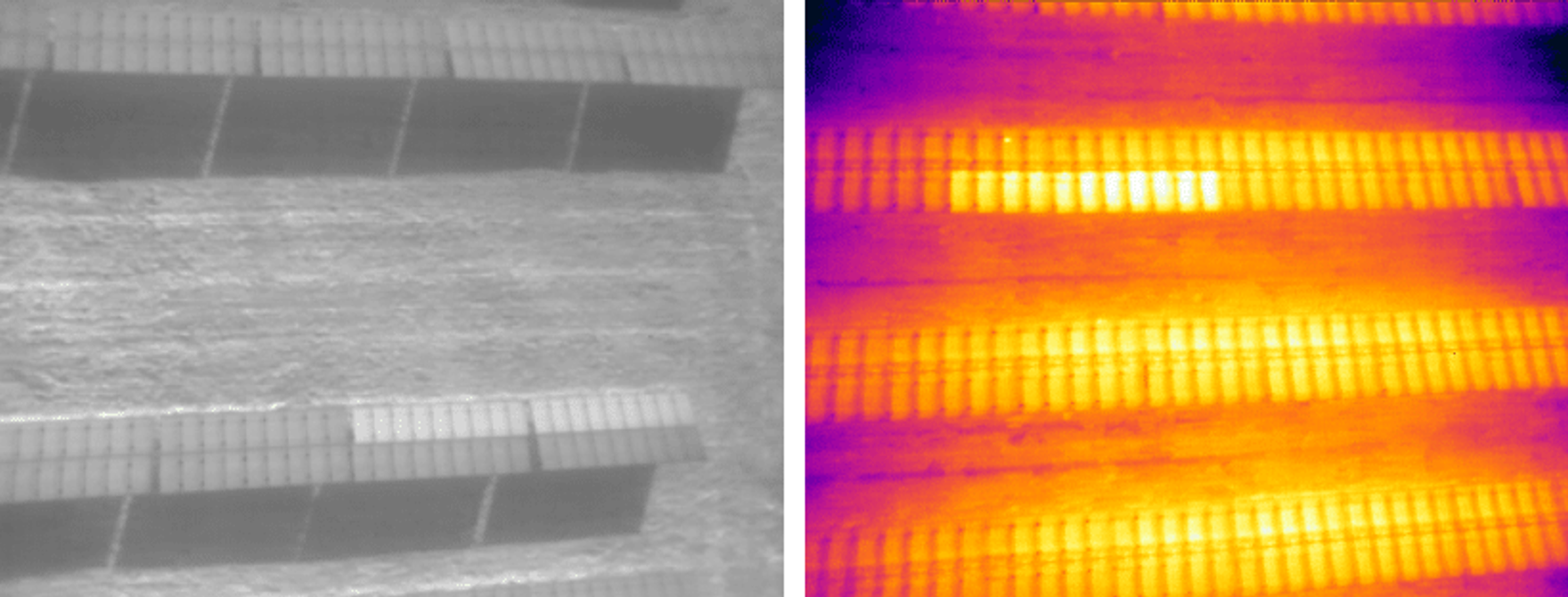

Detection of Module and System Faults Through Thermal Technology

Before drone technology, module and system faults were manually inspected by solar inspectors, navigating through rows of panels in order to collect data. When preforming a manual inspection, every individual module can’t be analyzed, and sometimes anomalies can be overlooked. With a thermal camera on a drone, an inspector or drone pilot can locate heat anomalies in a fraction of the time it would take to do it with a team of technicians inspecting on the ground. The most common heat anomalies include module level issues, such as shadowing, shattering, soiling (bird droppings), string level issues and alignment issues. Thermal drone technology can detect all of these abnormalities on a solar farm, even all the way down to the individual cell level. By capturing detailed imagery and data of the entire array, it’s easier to identify a problem that can be corrected without traversing acres of land.

Last year, the Nexamp team collectively closed the loop on a system concern, by leveraging Nexamp’s aerial infrared inspection technology. Our drone pilot identified two potential string faults at our Charlton Solar farm and Golden Hills Solar farm that had not found through our established fault detection methods. Through drone technology, the Nexamp team was able to confirm and correct both faults, one which was due to a blown fuse and the other a loose (but not disconnected) string.

Cost Efficient

As solar developers continue to seek operations and maintenance savings, drones and aerial data technologies are set to have a major impact in the solar energy industry. Through drones, solar developers can complete inspections in a fraction of the time, while saving on inspection costs. In fact, drones cut the cost of thermographic inspection of utility-scale solar farms between 30 and 40 percent and lowers inspection time from about a month to a week. Drone and aerial data provide more efficient inspections and reduce the overall cost of generating clean, solar energy.

Surveillance of Vegetation Management

Vegetation management can be a major concern for many solar developers. If a solar farm is left without surveillance, overgrown vegetation can obstruct energy production of an array. By getting a full aerial view through drone imagery, drones can capture vegetation condition images between and around solar panels.

The image above captured at our Arthur Hurley site in Dorchester, MA, draws some concern for the Nexamp team. They will need to keep an eye out on the production of the site, as the tree limbs casting shadows could cause coverage that could lead to a loss in energy production. Debris such as dust, pollen and bird droppings can also reduce the efficiency of a solar energy system.

The integration of drone and aerial technology continues to pioneer a safer and more efficient way for the solar and renewable energy industry.